Save this image free of charge

in 800 pixels for layout use

(right click, Save as...)

|

|

Ref : S01823

Theme :

Future projects - Exploration of the Solar System (136 images)

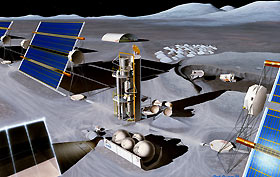

Title : Oxygen propellant derived from lunar raw materials could play a key role in reducing the amount of mass launched into low earth orbit to support a lunar base program and thus cut costs

Caption :

Oxygen propellant derived from lunar raw materials could play a key role in reducing the amount of mass launched into low earth orbit to support a lunar base program and thus cut costs. A program to manufacture lunar oxygen would involve a series of development stages on Earth and on the Moon to demonstrate process feasibility and to generate engineering data to support optimum one sixth g design of a full-scale production plant. The illustration shows a pilot plant sized to produce 2 mt per month of liquid oxygen. The plant reacts hydrogen gas with ilmenite to produce water and residual solids. The water is subsequently electrolytically separate into hydrogen and oxygen. The hydrogen is recycled to react with more ilmenite while the oxygen product is liquefied and stored. The feed stock for the depicted conceptual design is basalt rock mined from the bottom of a nearby crater. Oversized and undersized rocks are rejected at the pit site. The transported rock is loaded into a hopper and conveyed into a three-stage crushing,grinding circuit that reduces the rock size. Fine particles are separated by screens and discarded to a return conveyor. Ilmenite in the sized solid stream is concentrated prior to the reactor unit in a multi-roll high intensity magnetic separator. The reactor is a three-stage fluidized bed reactor. Reactor auxiliaries include low and high pressure feed hoppers, gas,solid cyclone separators, solid residual hopper, gas electric heater, blowers and hydrogen makeup system. A high-temperature, solid ceramic electrolysis cell is used to split reaction water to oxygen and hydrogen. The oxygen is liquefied and stored. After product certification, possible uses for the pilot plant oxygen include LOX reactant for fuel cells and to supplement oxygen requirements for life support systems. This production scheme is based on the carbotex process. Telerobotic application is extensive in this conceptual design to allow long-term operation of the plant without on-site human involvement.

|

|